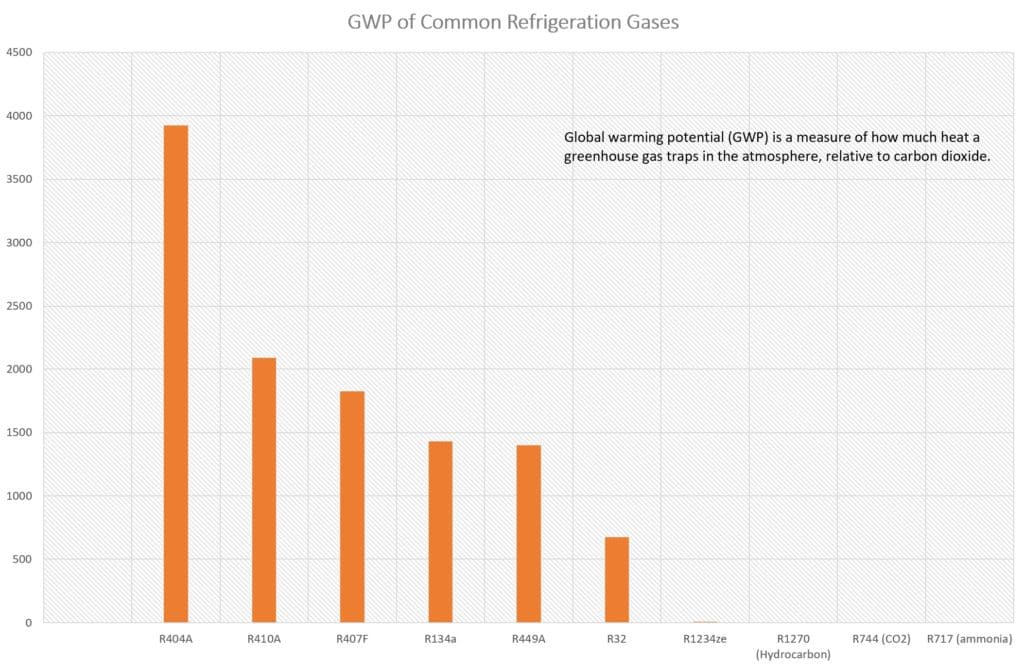

New F-gas regulations in the EU came into effect on 1st January 2020, so you should be aware of the basics if you work with refrigeration systems. The Fluorinated Greenhouse Gas Regulations ban the use of certain refrigerants if they have a Global Warming Potential (GWP) of more than 2500.

This means that all existing refrigeration units that exceed this limit, such as condensing units with over 10kg of HFC 404A, must comply with the ban. All users of these refrigeration systems can continue to run them until they break down, but technicians legally cannot service or repair them.

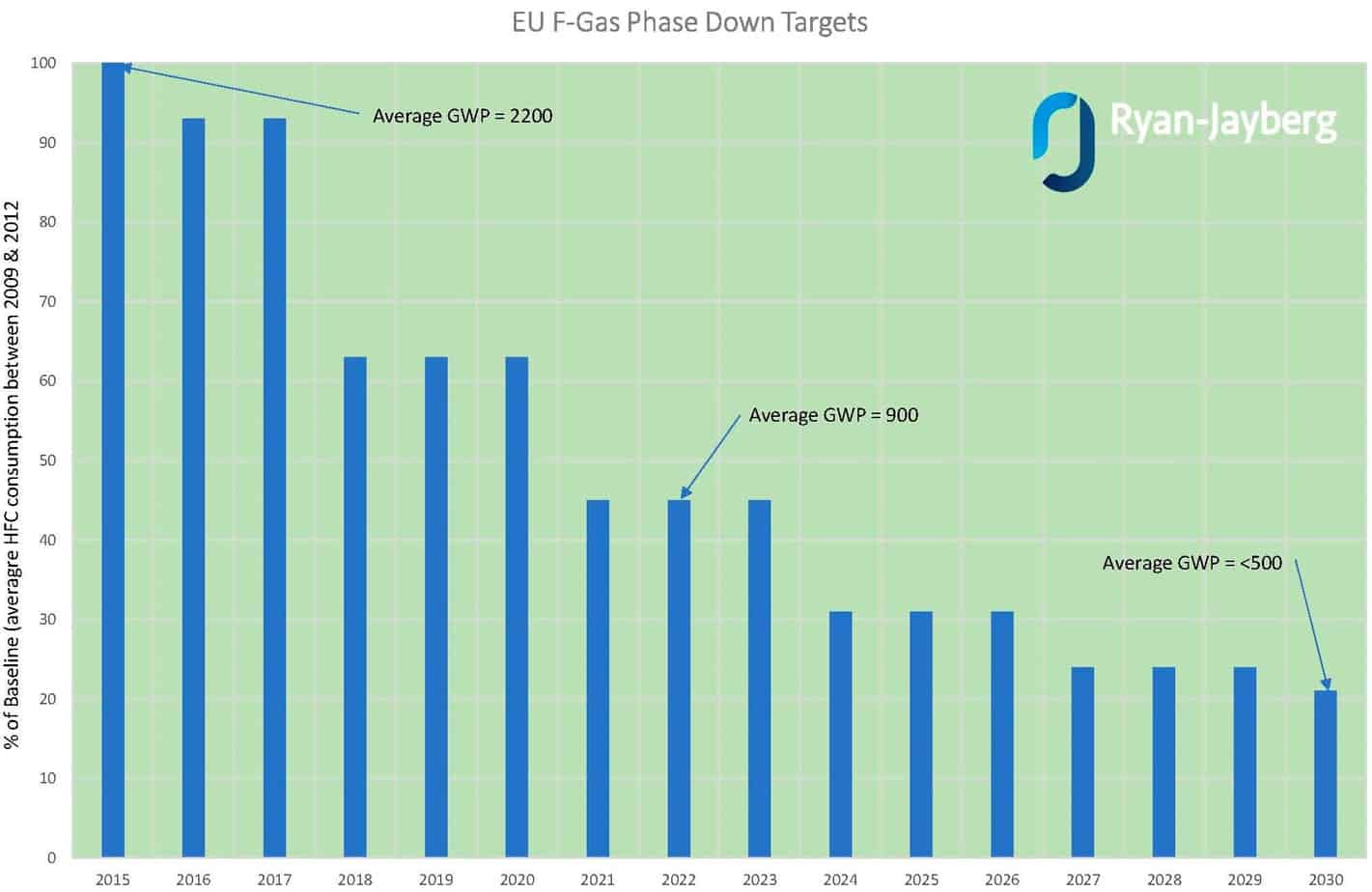

Knowing that the UK and EU are phasing down hydrofluorocarbons (HFCs) and other fluorinated gases over the next 10 years, you should have enough forewarning to make the switch to new refrigeration systems now that you can no longer top up your non-compliant units with F-gases.

Read-more... F-gases are commonly used as the coolant for older commercial refrigeration units. Therefore, the F-gas regulations will affect retailers and distributors using any of the following refrigeration systems, if their coolant is one of the banned F-gas refrigerants: Smaller units are not likely to be affected by the current ban, as the amount of refrigerant in their systems will be less than the maximum allowance. The ban will affect any unit that contains the equivalent of 40 tonnes of CO2 (e.g. 10kg of R404A, the most common F-gas coolant). If you haven’t already, then you should check whether your refrigeration systems are compliant immediately. If they aren’t, you could be subject to legal penalties, and repairs and replacements won’t be available for non-compliant units. The labels on your equipment should provide: Should there be no F-gas present, the equipment is probably exempt. However, the new regulations definitely apply if there is F-gas with a GWP of 2500 or above, and a CO2e of more than 40 tonnes. If you can’t find this information yourself or the labelling is unclear, consult the manufacturer of your refrigeration equipment. Alternatively, you can hire a qualified maintenance technician to assess the system for you. The phasing out of F-gases marks a revolutionary change for the refrigeration, heating, and cooling industries. These regulations will forever change the way that businesses operate. They not only apply to companies and traders based in Europe but also international businesses that operate within Europe. The next few years will see a continuous rapid decline in the availability of F-gases and a meteoric rise in prices as the market shrinks and gradually disappears. The quotas of HFC gases that manufacturers can supply in Europe will be cut to 21% by 2030, with strict regulations already imposed for leak-testing, labelling, and record-keeping. Any owner of a refrigeration system that uses F-gases is now under pressure to reduce or remove them. If you’re running an old F-gas system that starts leaking, leaving this unrepaired or topping up your system with more F-gas could not only be expensive, but also leaves you liable to prosecution for breaking the law over F-gas emissions. If your refrigeration equipment uses an F-gas below the ban’s threshold, you may be able to continue with coolant top-ups as normal. However, if your systems fall under the banned categories, then you now have three options for what you’re legally allowed to do: The F-gas laws apply to all sizes of businesses, including sole traders, companies, and partnerships in all sectors. So, if your job involves the use, installation, maintenance, or servicing of any equipment that uses F-gases, you need to adapt to the new regulations quickly to avoid fines and prosecution. Using the same F-gas from a recycled source might seem like the easiest route initially, but supplies will decrease over time. This means F-gases like R404A will be harder to find and more expensive to obtain. You’ll only be able to do this until 2030, anyway, when even recycled HFCs will be banned. Similarly, you might find that switching to a different F-gas with a lower GWP is cheaper than buying completely new refrigeration equipment. However, if the F-gas doesn’t work with your existing system, you’ll need to spend more on upgrading the equipment to facilitate the new gas anyway. The most forward-thinking alternative is to invest in new refrigeration systems that are compliant with the F-gas regulations from the start. This is obviously a costly undertaking, but there are several government schemes you can look into for loans or tax write-offs on energy-efficient equipment. Besides, if you fail to comply with the F-gas regulations, your business could be facing a fine of up to £200,000. Some businesses have already received fines of more than £1 million, so it’s really not worth the risk. Any decision you make around converting to a new refrigerant should take the lifespan of both the existing system and the replacement refrigerant into account. There are several HFC alternatives available, including natural refrigerants, F-gases with a lower GWP, hydrofluoroolefins (HFOs), or blends of these. The most common ‘natural refrigerants’ used to replace F-gases are carbon dioxide (CO2 or R744) and ammonia (NH3 or R717). Hydrocarbons and CO2 are the most popular replacement in domestic, commercial, and industrial refrigeration, as well as in air conditioning systems. There may be initial high costs involved in switching to or setting up a carbon dioxide refrigeration system – and the same for ammonia – but their efficiency and lower GWP means that their operating lifecycle will last a lot longer, with lower running costs over time. Do you need help assessing your refrigeration equipment for F-gas regulation compliance? Or could you benefit from expert advice on which F-gas compliance option is best for your business? As a long-standing refrigeration company with extensive knowledge of F-gas legislation, we’d be happy to help at Ryan-Jayberg. Simply get in touch with us by phone or email and we’ll see what we can do to help. You can reach us on 02089 446 288 or at info@ryan-jayberg.co.uk. Whether you need an F-gas engineer to service or replace your refrigeration system, or you’d like the F-gas regulations explained in more detail, the team at Ryan-Jayberg can assist you. Our F-gas certified HVAC experts are available at several branches across England for in-person support. F-gases is the shortened term for fluorinated greenhouse gases – but what exactly are they? As you’re probably aware, greenhouse gases are harmful emissions that trap heat in our atmosphere, contributing to global warming. This is why there are increasingly stricter regulations for their use. They’re basically synthetic chemicals that contain fluorine. There are three main types of F-gas: Fluorinated gases are found in many types of equipment, not just refrigeration systems. For example, air conditioning units, heat pumps, fire extinguishers, and cleaning solvents often use F-gases. Since they contribute to climate change, governments are phasing them out by 2030. These regulations restrict ozone-depleting substances and specifically set out a schedule for phasing out fluorinated greenhouse gases (F-gases), with usage requirements for manufacturers, suppliers, contractors, and consumers. The F-gas regulations aim to reduce the use of HFC refrigerants, through better control of their containment in existing applications and their recovery for recycling or destruction. This pushes businesses to change their habits and rely on alternatives that aren’t as harmful to the planet. Requirements of the F-gas regulations that will continue to be imposed include: Certain obligations will lie with the owner and/or operator of the equipment, while others will lie with third parties, such as suppliers, contractors, and waste handlers. If you produce, trade, or use fluorinated gases in any capacity, then you can find detailed guidance on how to follow F-gas regulations on the government website. This will tell you which gases you’re allowed to use and how you’re allowed to use them. Here’s a quick summary of F-gas restrictions: The permitted GWP, date of effect, and exemptions will depend on the specific type of F-gas and the specific product. Please click the links in the table above to view more detailed information on the current and future F-gas bans. In commercial and industrial refrigeration, there are several natural refrigerants that can be used in place of F-gases. These include the following gases as replacements for several HFCs/F-gases: There are also several hydrofluoroolefins (HFOs) and HFC-HFO blends available – while these still have a relatively high GWP, they’re still lower than HFCs, and usually suitable for retrofitting old refrigeration systems. The table below shows the most common HFC alternatives currently in use, from the lowest to the highest acceptable GWP, and whether these gases can be used to retrofit old equipment or must be used in new systems only. R717 – GWP 0 R744 – GWP 1 R1270 – GWP 2 R290 – GWP 3 R600a – GWP 3 R1234yf – GWP 4 R1234ze(E) – GWP 7 R513A – GWP 631 R32 – GWP 675 R449A – GWP 1397 R407C – GWP 1774 R407F – GWP 1825 R442A – GWP 1888 R410A – GWP 2088 R407A – GWP 2107 R427A – GWP 2138 R452A – GWP 2141 R438A – GWP 2265 R423A – GWP 2280 R417A – GWP 2346 R424A – GWP 2440 These regulations are in place to ensure that everyone involved in the production, distribution, sale, usage, or recovery of these harmful gases complies with the requirements to reduce F-gas emissions into the atmosphere. This includes both operators of the equipment containing F-gases – such as shop owners – and technicians who service and maintain this equipment. Anyone who is responsible for the functioning of the equipment is obligated to: When your equipment reaches the end of its working life, there’s also an obligation to make sure that all F-gases are properly recovered by a professional who is qualified to recycle or destroy them. To help you meet your legal obligations, it’s a good idea to set up a contract for regular planned refrigeration maintenance. This can be tailored to the specifications of your exact equipment. To ensure that all F-gas production and servicing is above board, it’s illegal for any business in this industry to operate without an F-gas certificate. This means that anyone who installs, maintains, or services stationary equipment that contains F-gas refrigerants must have the proper accreditation. This isn’t optional – it’s required by law to have valid F-gas certification if you’ll be handling F-gases on behalf of your own or another business. Employees must be F-gas certified as individuals, and the business as a whole needs an F-gas company certificate. Find out more on the government website: There are several certification bodies you can work with to receive accreditation, depending on the equipment you work with. The Environment Agency proactively enforces F-gas regulations, so you need to comply with the law if you don’t want to receive a fine or have your business shut down. We’re serious about health and safety at Ryan-Jayberg, so you can trust that our F-gas engineers are all appropriately qualified. You can check our REFCOM F-gas accreditation under the certificate number REF1011245. Show-lessWhich refrigeration systems use F-gases?

SMALL HERMETICALLY SEALED SYSTEMS

E.g. ice cream freezers, bottle coolers, standing retail displays with 0.1-0.5kg of refrigerant

CONDENSING UNITS

E.g. blast chillers, freezers, and commercial display cabinets in convenience stores

CENTRAL PACK SYSTEMS

E.g. large-scale refrigeration equipment in supermarkets with more than 100kg of coolant

How do I check for F-gas compliance?

What do the F-gas regulations mean for my business?

Use reclaimed or recycled R404A refrigerant

Hydrofluorocarbons (HFCs) are exempt from the ban until 2030 if reclaimed or recycled

Replace F-gas with a lower GWP refrigerant

Top up with a less harmful F-gas if it’s compatible – you may have to retrofit the system

Buy new equipment that uses a lower GWP refrigerant

Replace your old refrigeration system with new equipment that uses no or low F-gases

Which F-gas alternative is best for my business?

Should you update or replace your refrigeration system?

Where can I find an F-gas engineer?

F-Gas Regulation FAQs

What are fluorinated greenhouse gases?

What is the aim of the F-gas regulations?

Which F-gases are banned and which F-gases are exempt?

Current F-gas refill ban (introduced in 2020)

Current and future ban on new F-gas products (introduced from 2020 to 2023)

Hydrofluorocarbon (HFC) exemptions

Which replacements are available for F-gases?

Refrigerant gases with 2500 GWP or lower

Replacement for F-gases

Retrofittable or new equipment only

Ammonia

R134a

New equipment

Carbon dioxide

R134a, R404A

New equipment

Propene/propylene

R22, R404A, R410A

New equipment

Propane

R22, R404A, R410A

New equipment

Isobutane

R134a

New equipment

DuPont™ Opteon® YF/Solstice™ yf

R134a

New equipment

Solstice™ ze

R134a

New equipment

DuPont™ Opteon® XP10

R134a

Suitable for retrofitting existing equipment

Difluoromethane/difluoromethylene

R410A

New equipment

DuPont™ Opteon® XP40

R404A

Suitable for retrofitting existing equipment

Difluoromethane, pentafluoroethane, and tetrafluoroethane blend

R22

Suitable for retrofitting existing equipment (oil change necessary)

Genetron® Performax™ LT

R404A, R507, R22

Suitable for retrofitting most existing equipment

RS-50

R404A, R507, R22

Suitable for retrofitting most existing equipment

Difluoromethane and pentafluoroethane blend

R22

New equipment

Difluoromethane, pentafluoroethane, and tetrafluoroethane blend

R404A, R507, R22

Suitable for retrofitting most existing equipment

Forane® 427A

R22, R22 retrofit blends (R422D, R422A, R428A)

Suitable for retrofitting most existing equipment (oil change necessary)

DuPont™ Opteon® XP44

R404A

Suitable for retrofitting existing equipment

DuPont™ ISCEON® M099

R22, R22 retrofit blends (R422D, R422A, R428A)

Suitable for retrofitting most existing equipment (oil change necessary)

DuPont™ ISCEON® 39TC

R12

Suitable for retrofitting existing equipment

DuPont™ ISCEON® M059

R22, R22 retrofit blends

Suitable for retrofitting existing equipment

RS-44

R22, R22 retrofit blends

Suitable for retrofitting existing equipment

What are your legal obligations under the F-gas regulations?

What is an F-gas certificate?